Features:

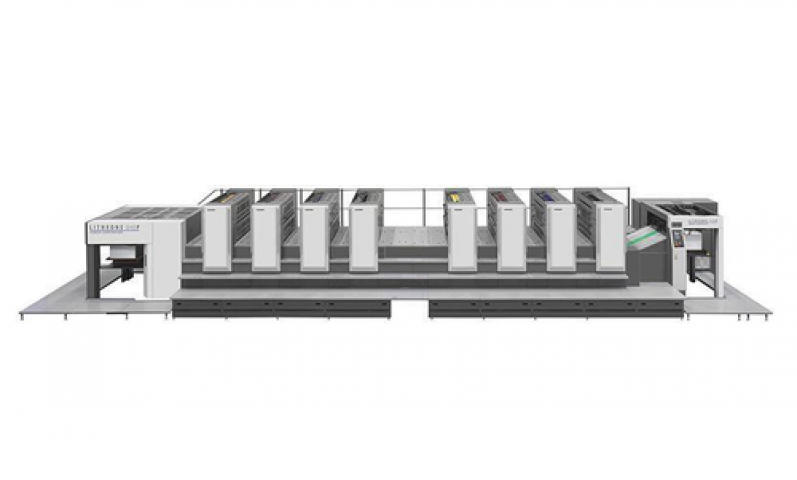

- Enables high-quality two-sided printing in one pass and straight multicolor printing in one machine.

- Equipped with Komori’s own high-performance perfecting mechanism configured by three double-size cylinders. Komori’s unique sheet transport system enabled by the stress-free sheet transfer and lower unit air control allows two-sided printing at 15,000 sheets per hour.

- Equipped with the Asynchronous Automatic Plate Changer (A-APC)* for significantly shorter makeready times. Furthermore, the Lithrone G40P is also equipped with the H-UV/H-UV L (LED)* system, which enables fast print drying and short turnarounds.

A wide range of other options is also available. - Superb performance with heavy stock in either single-sided or double-sided printing mode means that a variety of stunning high added value printing effects can be obtained with special inks and overprint varnish. The Lithrone G40P is a machine of matchless flexibility that addresses a variety of needs at the highest level.

Brand - Komori

Usage/Application - Printing

Model Name/Number - LITHRONE G40P

Delivery Pile Height - 1,380 mm

Plate Size - 800x1030 mm

Max. Printing Area - 710x1020 (Single-sided),700x1020 (Double-sided) mm

Number Of Colors - 4-8,10

Max. Sheet Size - 720x1030

Feeder Pile Height - 1,450 mm

1923:- Komori Machine Works is founded in Kitashinmachi, Honjo-ku, Tokyo (present Higashikomagata,Sumida-ku, Tokyo).1925:- Lithograph roll printing press is developed.1928:- Manual sheetfed 32-inch offset press is developed.1946:- Komori Printing Machinery Manufacturing Co., Ltd. is founded in Azumabashi, Sumida-ku,Tokyo (present Head Office). Osaka Representative Office is established (present Osaka Regional Headquarters in Osaka City).1957:- First Komori four-color offset press (UM-4C) is developed.1961:- Dry offset banknote press is delivered to the Japan Printing Bureau, Ministry of Finance.1967:- Toride Plant is established.1968:- “Komori Printing School,” first of its kind in the industry, is established.1975:- Service Center is established.1976:- Company name is changed to Komori Printing Machinery Co., Ltd.1978:- Sekiyado Plant is established.1982:- Komori America Corporation (in the suburb of Chicago) is established.1983:- Shares are listed on the Second Section of the Tokyo Stock Exchange.1984:- Shares are listed on the First Section of the Tokyo Stock Exchange. Komori Europe Limited (present Komori U.K. Limited) in Leeds, U.K., is established.1986:- Komori Yamagata Machinery Plant is completed which specializes in the production of smallsized sheetfed presses, resulting in a three-plant organization with Toride Plant for mediumsized press production and Sekiyado Plant for large sheetfed, web offset and special press production.1988:- Komori Europe B.V. (present Komori International (Europe) B.V., in Maachen, the Netherlands), is established. The first securities press for export is delivered to the Korea Security Printing and Minting Corporation.1989:- Komori-Chambon SA (in Orleans, France) is established.1990:- Company name is changed to Komori Corporation and names of group companies in Japan are revised accordingly. Company stock is recognized as loan transaction stock by both the Tokyo Stock Exchange & Osaka Securities Exchange. Full-APC, the world’s first automatic plate-changer, is developed.1991:- Groundbreaking of Head Office is performed. APC development is honored with awards from the Japanese Society of Printing Science and Technology and the Japan Society for the Promotion of Machine Industry.1992:- Groundbreaking of Techno Service Center is performed.1996:- Full banknote printing lines are delivered to the Reserve Bank of India.1997:- Komori KHS System is developed. “Lithrone 40 SP,” two-sided multicolor offset press, is developed.1998:- Komori Hong Kong Limited (KHK) is established.1999:- Sales of the Lithrone series products exceed 10,000 units. Full banknote printing lines are delivered to the Nigerian Security Printing and Minting Co., Ltd.2001:- Parts Service Center is established. Rights to development, production, sales, and service of web offset presses (including those for books and publications) from Toshiba Machine Co., Ltd., are granted.

2002:- 1st Phase construction of Tsukuba Plant is completed and operation starts. The cutting-edge machine “Lithrone S40” is developed.2003:- Qualifying is completed for the ISO 14001 certification for all divisions.2004:- Komori calendar of 2004 receives the “Prime Minister Prize” at the 55th Japan Calendar Exhibition. Web Offset Press “SYSTEM 35S” is developed.2005:- 2nd Phase construction of Tsukuba Plant is completed and integrates Toride Plant.2006:- Komori Printing Machine (Shenzhen) Co., Ltd. (KSZ) is established.2007:- 44″ Offset Printing Press “Lithrone S44” is announced at IGAS2007.2008:- 40″ Offset Printing Press “Lithrone SX40” is announced at drupa2008.2009:- 3rd Phase construction of Tsukuba Plant is completed and integrates Sekiyado Plant. Komori Graphic Technology Center is opened in the extended space.2010:- 29″ Offset Printing Press “Enthrone29” is announced at IPEX2010.